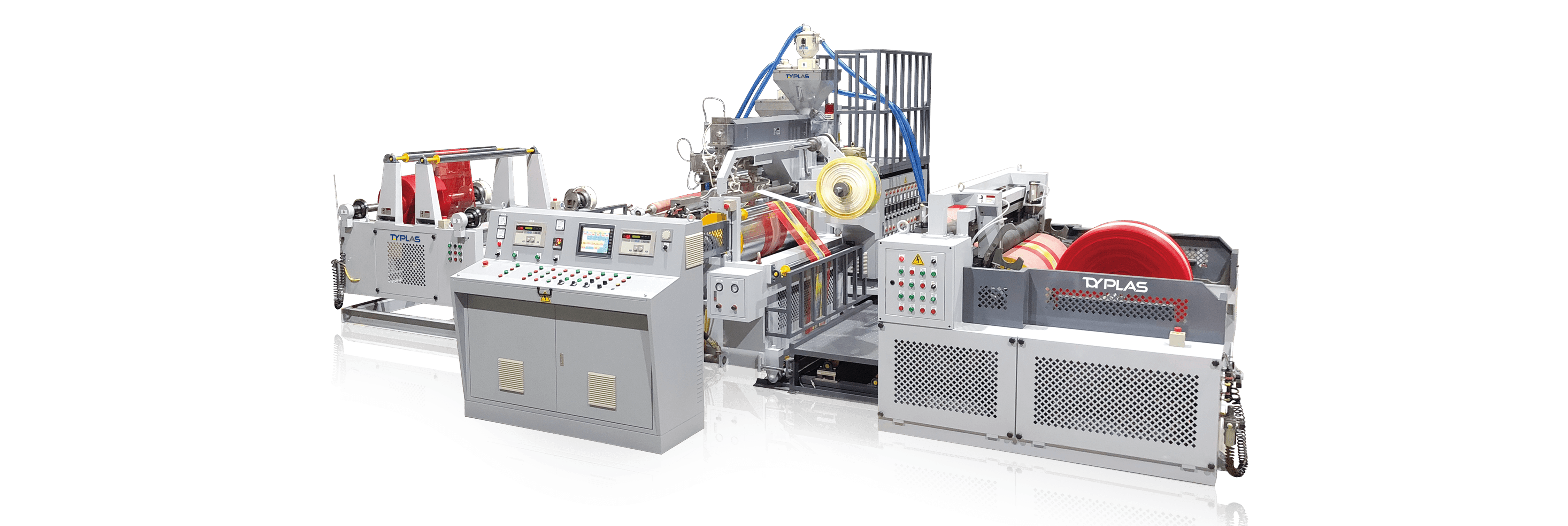

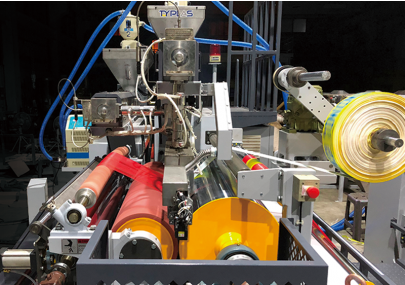

The main functions of the LMLB series can be made of two kinds of film at the same time. First is onion mesh cloth and printing leno through the lamination for bonding in the middle. Second is to laminate the film about 70-100 mm wide at the side, and this side film will do hole-punching process and used as auto filling and packing.

☆ 1. Equipped with machine interlocking operation, H.M.I program control & PLC, and simple operation for high efficiency

☆ 2. Automatic unwinding, automatic winding change speed reduce to 30-50M/MIN

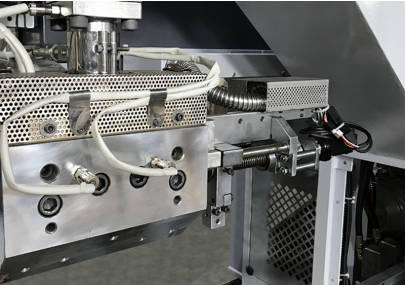

☆ 3. Automatic adjustment of T-die, automatic tension control

☆ 4. Provide MAGUIRE blender, cooling chiller, air compressor, crane device, and leno unwinder with E.P.C control as optional

☆ 5. Production speed from 10-150 M/MIN* The capacity of extrusion is 100-150KG/HR

| ITEM/MODEL | TY-LMLB45-45-11SW | TY-LMLB55-55-11SW |

| Two Extruder Max. Capacity | 45 kg/ hr & 45 kg / hr | 70 kg/ hr & 70 kg / hr |

| Max. Line Speed | 100 m / min | 150 m / min |

| Coating Thickness | 0.025 mm - 0.08 mm | 0.025 mm - 0.08 mm |

| Screw Diameter / Multiple | 45 mm / 32D & 45 mm / 32D | 55 mm / 32D & 55 mm / 32D |

| T-die Width | 420 mm & 270 mm | 420 mm & 270 mm |

| Label Coating Width | 110 mm - 260 mm | 110 mm - 260 mm |

| Side Film Coating Width | 70 mm - 100 mm | 70 mm - 100 mm |

| L x W x H | 7600 mm x 7000 mm x 2800 mm | 7700 mm x 7800 mm x 2900 mm |