EN

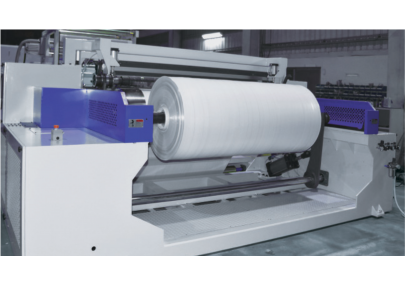

Jumbo Bag Laminating Machine

LMJB Series

Introduction:

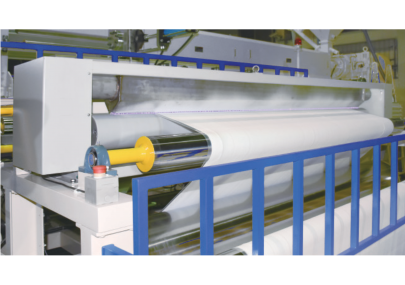

The LMJB series is a production line of plastic extrusion laminating machine. This machine is specifically designed for laminating PP circular woven jumbo bags. Its main design feature ensures that after laminating, the PP circular woven jumbo bags have a smooth surface without wrinkles, in addition to strong adhesion.

Purpose:

The LMJB series serves two main laminating functions:

☆ 1. Double-sided lamination of PP circular woven jumbo bags, which requires two coating processes to complete with one extruder. On the other hand, double-sided lamination can also be completed in one step with two extruders.

☆ 2. Single-sided lamination of PP woven jumbo bags, which requires one coating process.

Features:

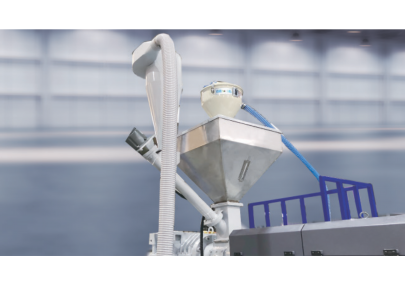

☆ 1. A special screw design generates high-quality thin films with uniform discharge.

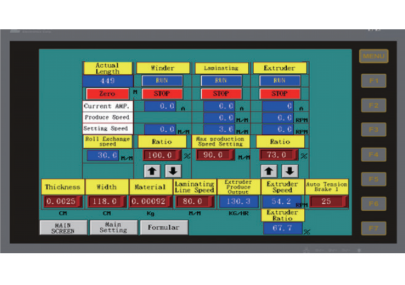

☆ 2. Equipped with PLC programming and an HMI device, facilitating thickness setting, synchronized speed control, and parameter memory in operation.

☆ 3. Unwinding unit automatically detects fabric insertion, while the winding unit can automatically change fabric rolls based on preset length.

☆ 4. The unwinding unit and winding unit maintain fabric roll flatness through an automatic tension control system and specially designed guide wheels.

☆ 5. Customized designs are available according to customer requirements.

Feature

Unwinding unit configures with missing fabric detection and automatic unwinding change device; not only running with mag

PLC program with a user-friendly HMI touchscreen interface, interlocking operation of all units and data memory as optio

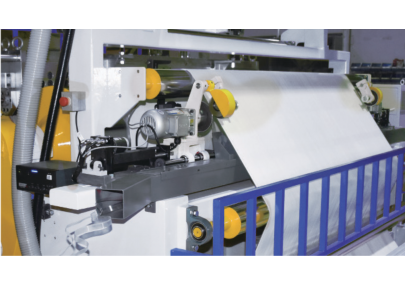

Automatic EPC edge trimming and cutting device, with provision to reserve extra film width without cutting into the fabr

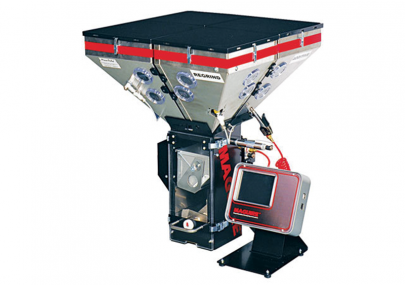

Edge material recycling device, where the trimmed material is crushed and directly mixed with the raw material before ex

The winding unit is equipped with automatic length measuring and cutting function for fabric roll change.

Specification

| ITEM/MODEL | TY-LMJB115-22S | TY-LMJB120-24S | TY-LMJB115-22D | TY-LMJB120-24D |

| EXTRUDER MAX. CAPACITY | 350kg / hr | 400kg / hr | 350kg / hr × 2 | 400kg / hr × 2 |

| MAX.LINE SPEED | 100 m / min | 100 m / min | 100 m / min | 100 m / min |

| COATING THICKNESS | 0.03 mm - 0.05 mm | 0.03 mm - 0.05 mm | 0.03 mm - 0.05 mm | 0.03 mm - 0.05 mm |

| SCREW DIAMETER/MULTIPLE | 115 mm/32D | 120 mm/32D | 115 mm/32D × 2 | 120 mm/32D × 2 |

| T-DIE WIDTH | 2250 mm | 2450 mm | 2250 mm | 2450 mm / min |

| COATING WIDTH | 1050 mm – 2050 mm | 1050 mm – 2250 mm | 1050 mm – 2050 mm | 1050 mm – 2250 mm |

| PP JUMBO BAG WEIGHT | 180 - 240 gsm/㎡ | 180 - 240 gsm/㎡ | 180 - 240 gsm/㎡ | 180 - 240 gsm/㎡ |

| L x W x H | 12000mm × 10000mm × 2800mm | 13000mm × 11000mm × 2900mm | 12000mm × 14000mm × 2900mm | 13000mm × 14000mm × 3000mm |