EN

Three Layer PP Tape Line Making Machine

TY - TLTM Series

Features & Advantages

☆ 4. Laminating adhesion is better and less powder on the surface of yarn.

☆ 5. The ABA three layers pulling tesion is stronger than single layer.

SPECIFICATION

☆ 1. Max. line speed: 380 m/min

TYPLAS’s TLTM series is mainly used in PP, HDPE tape line production, it is used for weaving by circular loom and flat loom into tubular woven bags, onion bags, FIBC fabrics, tents, and waterproof tarpaulin.

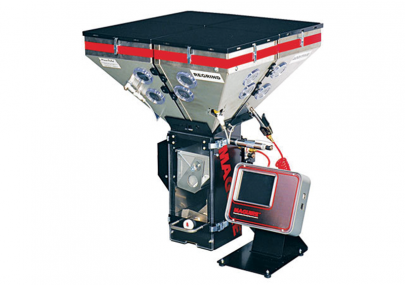

☆ 1. The A layer of ABA three layer can add 3%~5% modifier and the B layer can add up to 28% modifier.

☆ 2. The surface of film is clean, bright and smooth as new.

☆ 3. It helps the film to dehydrate efficiently running at high constant speed.☆ 4. Laminating adhesion is better and less powder on the surface of yarn.

☆ 5. The ABA three layers pulling tesion is stronger than single layer.

SPECIFICATION

☆ 1. Max. line speed: 380 m/min

☆ 2. Max. capacity: 620 kg/hr

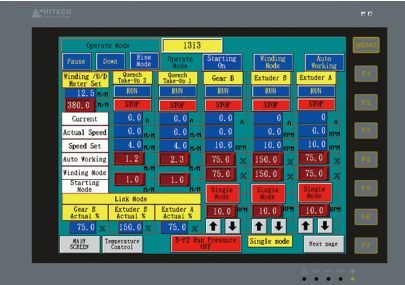

☆ 3. PLC programing and human machine interface with interlocking operation

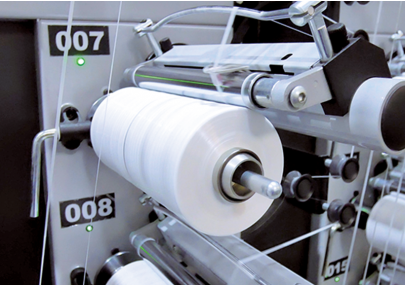

☆ 4. Tape winder can set the diameter value of tape for winder change warning by LED light

☆ 5. Three layer co-extrusion Improve the physical property of tape to the highest tensile strength and tension

Feature

Inverter type and automatic tension control winder, the light-weight design of the tape guide slide achieves power savin

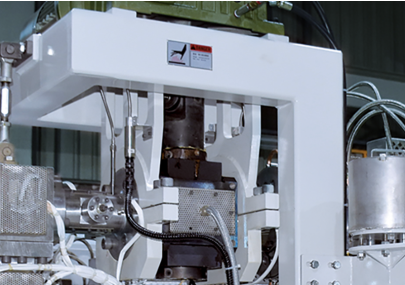

The double extrusion goes through the feed block device and the special T-die runner to make the three-layer A.B.A co-ex

MEC-P-150 Thickness measuring machine, the use of Germany imported infrared MF electric eye, measurement accuracy of 5um

Specification

| ITEM/MODEL | TY-TLM75-95-1100-180-ST1 | TY-TLM80-105-1300-216-ST1 | TY-TLM90-115-1500-252-ST1 |

| Max. CAPACITY | 420kg / hr | 520kg / hr | 620kg / hr |

| Max. Line Speed | 380 m / min | 380 m / min | 380 m / min |

| Denier | 600 - 1200 | 600 - 1200 | 600 - 1200 |

| Screw Diameter / Multiple | A Extruder : 75 mm / 33D B Extruder : 95 mm / 33D | A Extruder : 80 mm / 33D B Extruder : 105 mm / 33D | A Extruder : 90 mm / 33D B Extruder : 115 mm / 33D |

| T-die Width | 1100 mm | 1300 mm | 1530 mm |

| Effective Width | 990 mm | 1190 mm | 1400 mm |

| Auto Tension Take-up Winder | 180 pcs | 216 pcs | 252 pcs |

| L x W x H | 39000 mm x 4700 mm x 4050 mm | 41000 mm x 4900 mm x 4150 mm | 43000 mm x 5100 mm x 4250 mm |