EN

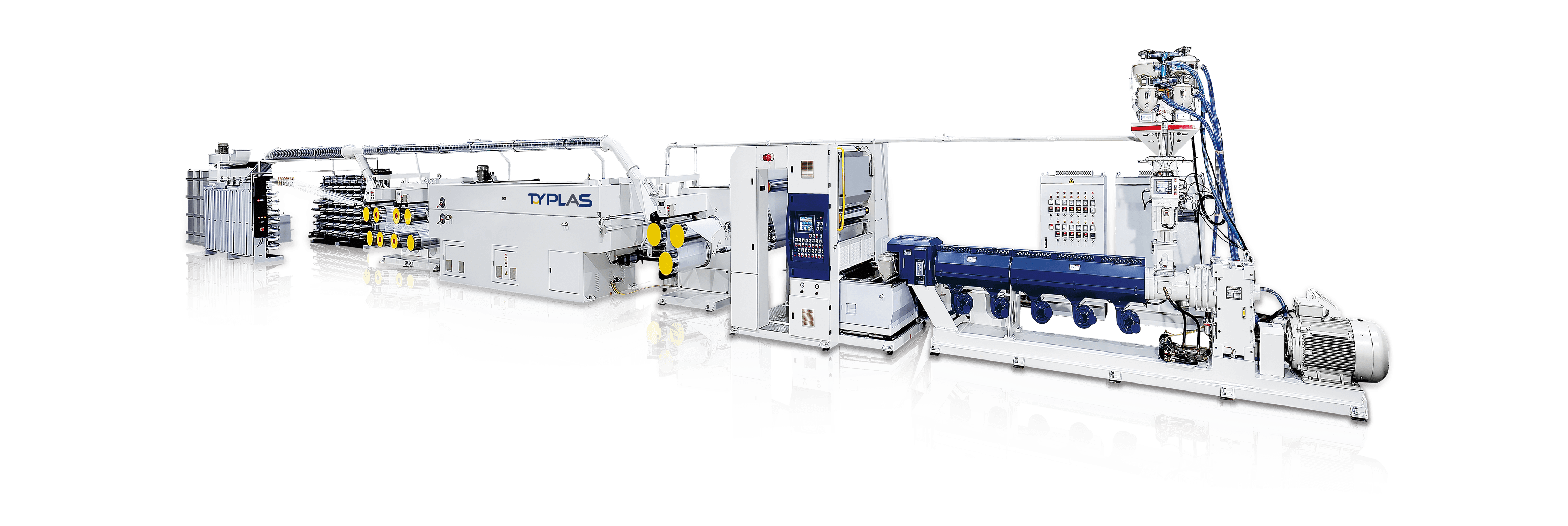

PP /HDPE Tape Line Jumbo Making Machine

TY-TLJM Series

Features & Advantages

TLJM series is mainly used in PP & HDPE high denier tape production, it used for weaving by circular loom and flat loom into tubular jumbo bags, FIBC fabrics, tents, geotextiles and waterproof tarpaulin.

☆ 1. Line speed: 180-380 m/mins

☆ 2. Max. capacity: 620 kg/hr

☆ 3. Special screw design to produce high quality and stable extrusion.

☆ 4. Improve the physical property of tape to the highest tensile strength and tension.

☆ 5. PLC programing and human machine interface with interlocking operation.

☆ 6. Stretching oven with airflow and temperature stability design.

☆ 7. Annealing pre-heater roller and cooling device makes the tape physical property stable.

☆ 8. Tape winder can set the diameter value of tape for winder change warning by LED light.

☆ 9. Tape folding device as optional equipment.

☆ 10. Machine customization

Feature

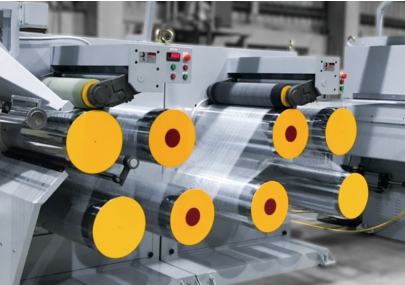

Inverter type and automatic tension control winder, the light-weight design of the tape guide slide achieves power...

The design of air volume rectifier and uniform heating inside the extended oven makes the high denier tape achieve...

The process design of stretching and preheating roller make high denier tape to achieve the tape stability.

High denier tape adopts two-component knife with non-stop design and swing device to increase production efficiency and

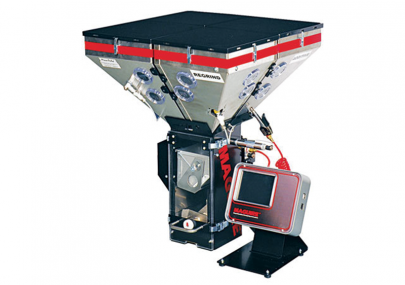

Quench take-up unit, with extrusion device, film cooling forming, and water removal system to keep the film even.

Specification

| ITEM/MODEL | TY-TLJM110-1100-240-ST1 | TY-TLJM120-1120-228-ST1 | TY-TLM130-1250-252-ST1 |

| Max. Capacity | 450 kg/ hr | 520 kg/ hr | 620 kg/ hr |

| Max. Line Speed | 180 - 380 m / min | 180 - 380 m / min | 180 - 380 m / min |

| Denier | 600 - 2500 | 600 - 2500 | 600 - 2500 |

| Screw Diameter / Multiple | 110 mm / 34D | 120 mm / 34D | 130 mm / 34D |

| T-die Width | 1000 mm | 1120 mm | 1250 mm |

| Effective Width | 900 mm | 1010 mm | 1130 mm |

| Auto Tension Take-up Winder | 240 pcs | 228 pcs | 252 pcs |

| L x W x H | 41000 mm x 4600 mm x 4050 mm | 43000 mm x 4750 mm x 4150 mm | 45000 mm x 4900 mm x 4250 mm |