EN

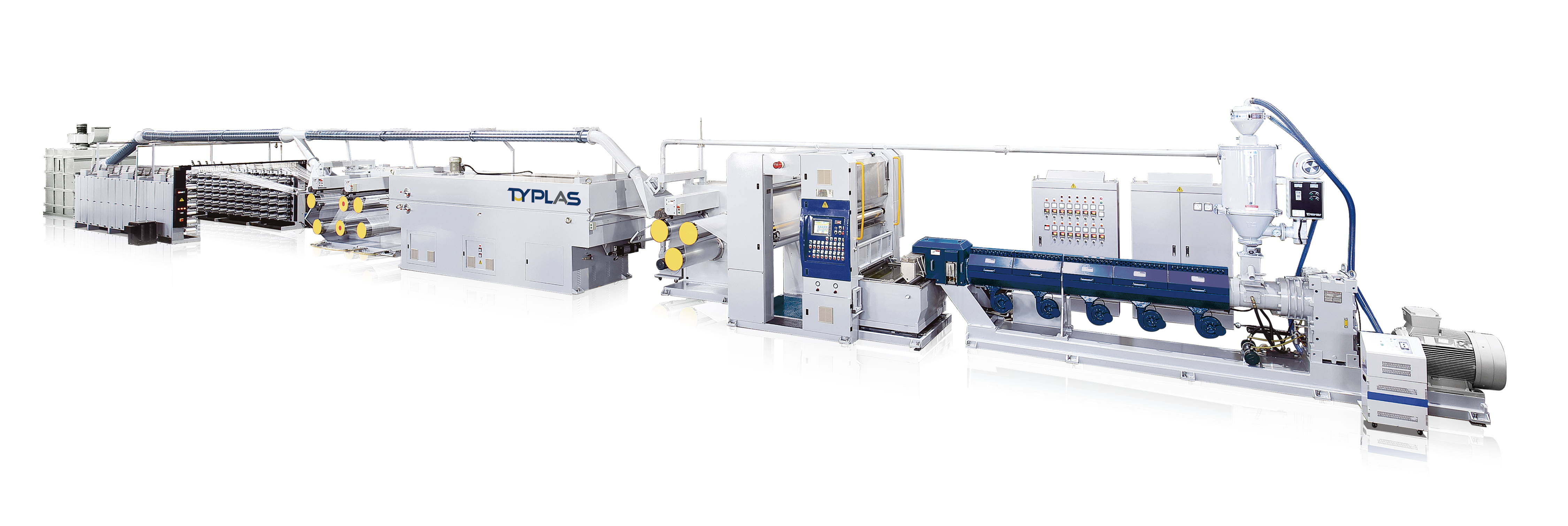

PP Tape Line Making Machine

TY-TLM Series

Feature & Advantages

TLM series is mainly used in PP, HDPE tape line production, it used for weaving by circular loom and flat loom into tubular woven bags, onion bags, FIBC fabrics, tents, and waterproof tarpaulin.

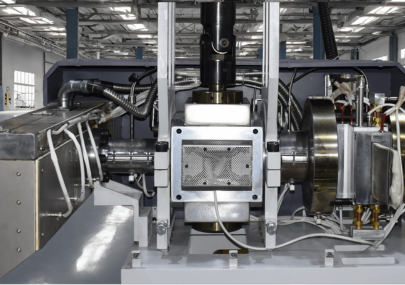

☆ 1. Double layer auto filter change and T-die thermal insulation design

☆ 2. Melt pump (optional), its function is to maintain the quality and stability of the extrusion

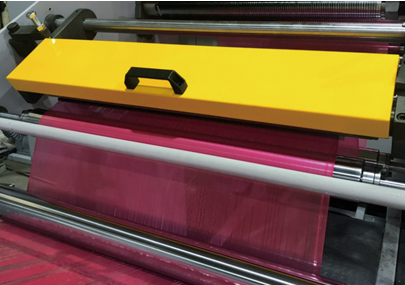

☆ 3. Quench take-up unit, with extrusion device, film cooling forming, and water removal system to keep the film even

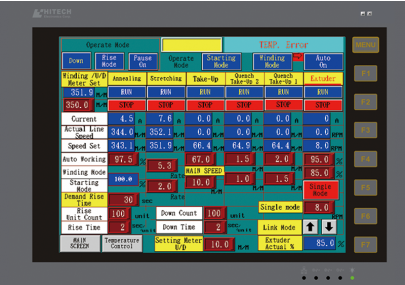

☆ 4. PLC program control & HMI interface, easy to operate and data memorize

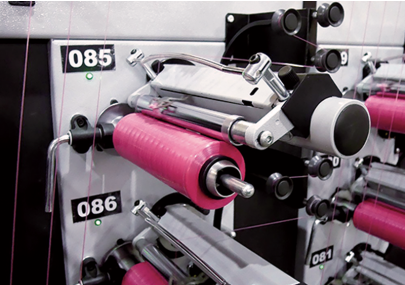

☆ 5. 5 sets slitting knife with swing device and non-stop design

☆ 6. Inverter type and automatic tension control winder, the light-weight design of the tape guide slide achieves power saving performance, and the winding shaft is equipped with a hooking device to facilitate the roll change

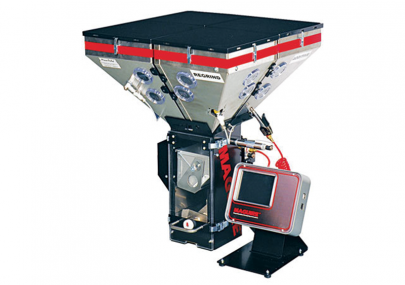

☆ 7. MAGUIRE blender(optional), and its function is to automatically cut and mix according to the proportion of raw material

Feature

Quench take-up unit, with extrusion device, film cooling forming, and water removal system to keep the film even.

Inverter type and automatic tension control winder, the light-weight design of the tape guide slide achieves power savin

Specification

| ITEM/MEDEL | TY-TLM110-1100-180ST1 | TY-TLM-120-1300-216ST1 | TY-TLM130-1500-252ST1 |

| Max. CAPACITY | 420KGF/HR | 520KGF/HR | 620KGF/HR |

| Max. Line Speed | 380 m / min | 380 m / min | 380 m / min |

| Denier | 500 - 1200 | 500 - 1200 | 500 - 1200 |

| Screw Diameter / Multiple | 110 mm / 34D | 120 mm / 34D | 130 mm / 34D |

| T-die Width | 1100 mm | 1300 mm | 1530 mm |

| Effective Width | 990 mm | 1190 mm | 1400 mm |

| Auto Tension Take-up Winder | 180 pcs | 216 pcs | 252 pcs |

| L x W x H | 39000 mm x 4700 mm x 4050 mm | 41000 mm x 4900 mm x 4150 mm | 43000 mm x 5100 mm x 4250 mm |

Detailed introduction

TY-TLM SERIES

This equipment was design for special screw and dosing material,reduce the waste.high efficiency and high quality.Special design for take up roller and remove water equipment,high speed was dry.Non stop in slitter Six sets for Gravimetric Batch Bladers and move bar,extend the blade use time.Thinkness measurement system was optional equipment,it can keep the denier quality and stable,.HMI setting temperature and speed,PLC to controller.Automatic increased speed,Reduce,operational easy.

TY-TLM SERIES

This equipment was design for special screw and dosing material,reduce the waste.high efficiency and high quality.Special design for take up roller and remove water equipment,high speed was dry.No stop in slitter Six sets for Gravimetric Batch Bladers and move bar,extend the blade use time.Thinkness measurement system was optional equipment,it can keep the denier quality and stable,.HMI setting temperature and speed,PLC to controller.Automatic increased speed,Reduce,operational easy.