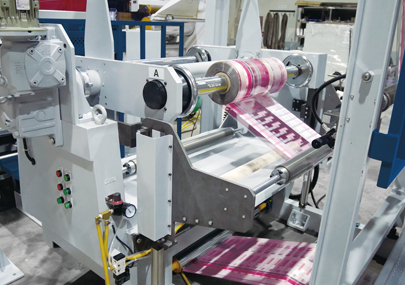

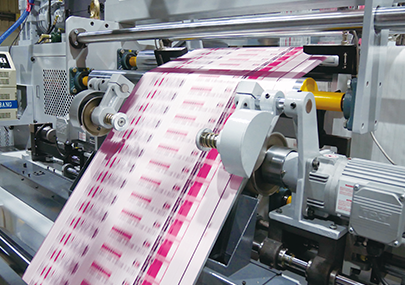

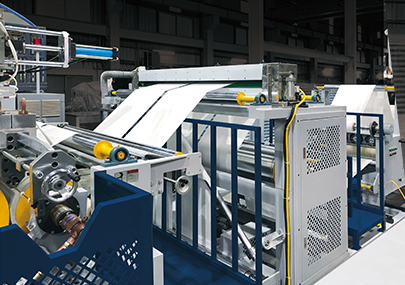

LMBO series is an extrusion laminating machine. This model is used for lamination between PP woven cloth and BOPP printing film, and that design produces bonding effect.

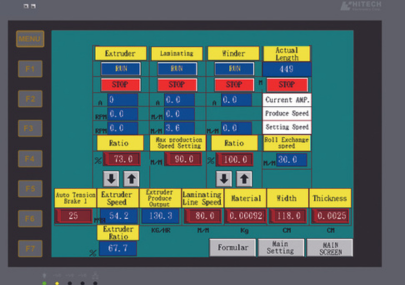

Automatic operation control is the main feature.

Features & Advantages

The main function of the LMBO series is to make two types of film. First is PP tubular woven cloth double side lamination. PP Tubular woven cloth goes through turn bar device, then the two side is completed laminated at the same time. Second is lamination by double side of PP tubular woven cloth and BOPP printing film, and the main feature is that the two sides of the printing point can reach automatic peering.

☆ 1. Production speed is divided into 100 m/min and 180 m/min models

☆ 2. Special screw design to produce high quality and stable discharge.

☆ 3. PLC programing and human machine interface makes more convenient to set the film thickness, speed synchronous control, and automatic roll change

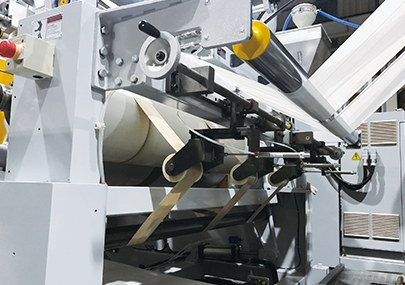

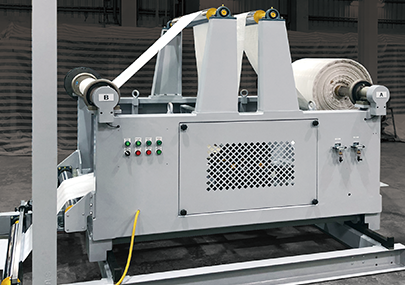

☆ 4. Unwinder is equipped with automatic cloth connect, and the winder can be used for meter set automatic cloth change function

☆ 5. The unwinder and winder through the automatic tension control system, which can keep the smoothness of cloth

☆ 6. Machine customization

| ITEM/MODEL | TY-LMBO90-16-08SWD | TY-LMBO95-18-09SWD | TY-LMB110-18-09SWD | TY-LMBO115-18-09SWD |

| Extruder Max. Capacity | 200 kg / hr | 240 kg / hr | 360 kg / hrv | 420 kg / hr |

| Max. Line Speed | 100 m / min | 100 m / min | 180 m / min | 180 m / min |

| Coating Thickness | 0.018 mm - 0.05 mm | 0.018 mm - 0.05 mm | 0.018 mm - 0.05 mm | 0.018 mm - 0.05 mm |

| Screw Diameter / Multiple | 90 mm / 32D | 95 mm / 32D | 110 mm / 32D | 115 mm / 32D |

| T-die Width | 1650 mm | 1850 mm | 1650 mm | 1850 mm |

| Coating Width | 350 mm - 680mm | 350 mm - 780 mm | 350 mm - 680 mm | 350 mm - 780 mm |

| PP Tubular Colth Weight | 60 - 100 gsm / m2 | 60 -100 gsm / m2 | 60 - 100 gsm / m2 | 60 - 100 gsm / m2 |

| L x W x H | 13000mm × 11000mm × 3600mm | 13000mm × 11500mm × 3700mm | 14000mm × 12200mm × 3900mm | 14000mm × 12800mm × 4000mm |