EN

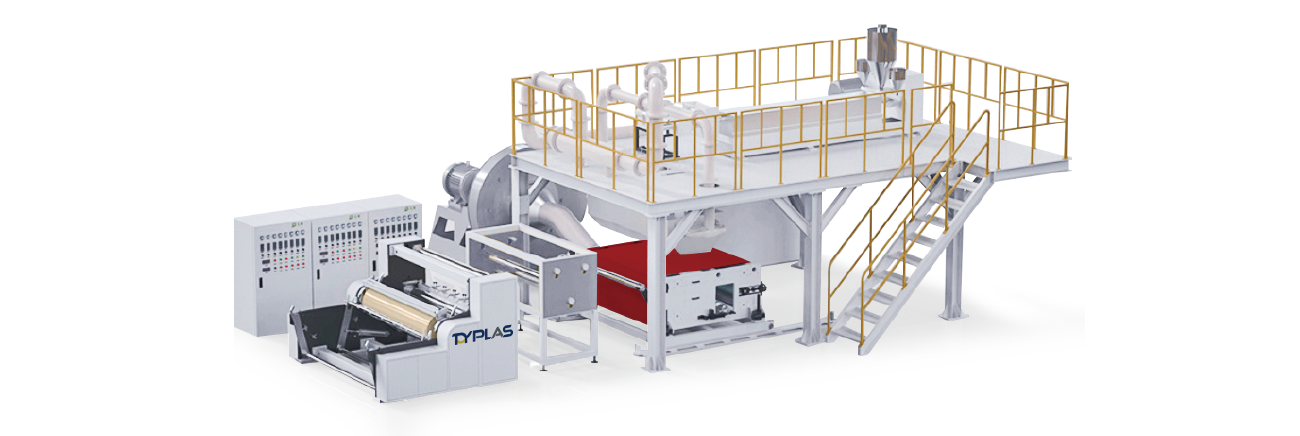

PP Meltblown Nonwoven Fabric Making Machine

NWMB Series

NWMB series meltblown nonwoven fabric production line is based on Polypropylene (PP). After hightemperature melting directly sprayed microfibers, fiber diameter up to 2 to 5 microns, also the unique capillary structure of microfibers can increase the number of fibers per unit area and surface area, so that the meltblown nonwoven cloth has a good filtration, insulation and oil absorption.

APPLICATIONS OF MELTBLOWN NONWOVEN FABRIC:

Meltblown nonwoven products have a wide range of applications, including thermal insulation, oil absorption, air filtration, liquid filtration, medical materials, and composite materials.

Automotive air filter material. Face mask: N95, Medical and surgical masks, Industrial and activated carbon mask.☆ 1. Filter products :

H10-H14 high-efficiency filter material for air purifiers, air conditioners and dust-free rooms.

H10-H14 high-efficiency filter material for air purifiers, air conditioners and dust-free rooms.

☆ 2. Thermal insulation products :

Snow jackets, snowshoes, gloves, cold-proof fillers, etc.

Snow jackets, snowshoes, gloves, cold-proof fillers, etc.

☆ 3. Oil absorption products :

Rivers to prevent and control pollution, oil absorption treatment, wipe cloth.

Rivers to prevent and control pollution, oil absorption treatment, wipe cloth.

FEATURE & ADVANTAGES

☆ 1. Max. Line speed: 40 m/min, maximum width: 1600mm, production specification 20-35 gsm*.

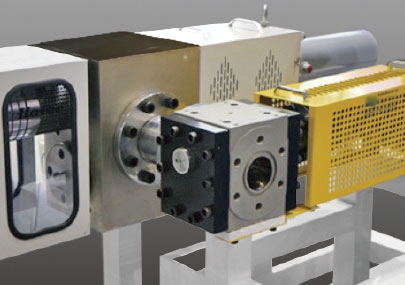

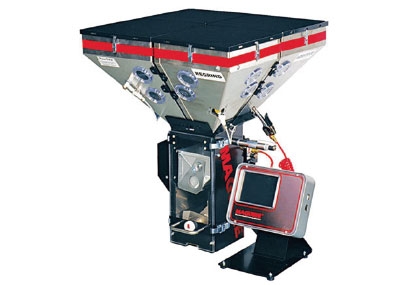

☆ 2. Special screw design to produce high quality and stable discharge.

☆ 3. PLC programing and human machine interface with interlocking operation and auto roller change.

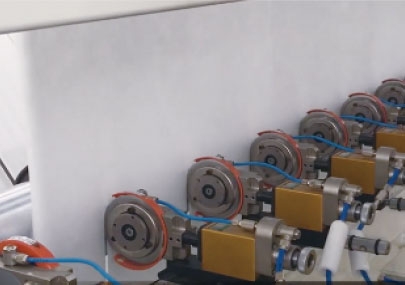

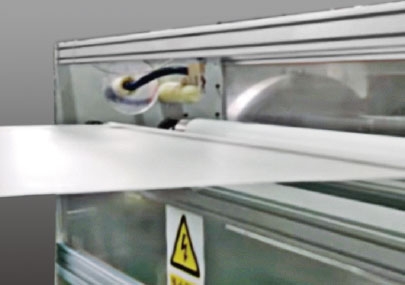

☆ 4. Using electrostatic electret technology, the static electricity is attached to the fibers of the meltblown nonwoven fabric.

The filtration efficiency of masks and other filtration products can be greatly improved.

The filtration efficiency of masks and other filtration products can be greatly improved.

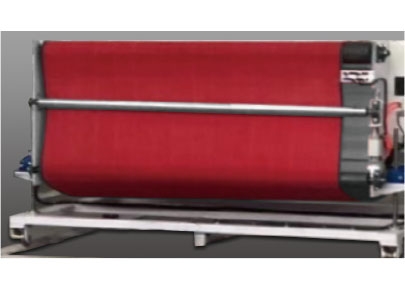

☆ 5. The unwinder and winder through the automatic tension control system, which can keep the smoothness of the meltblown nonwoven fabric.

☆ 6. Machine customization.

Feature

Use imported high quality steel to make precision spinneret hole of die, and the appearance is designed with insulation

The winder is designed for automatic length calculation, cloth cutting and roll change, which is easy to operate.

Use device of electrostatic electret technology, and the static electricity is absorbed in the meltblown nonwoven fiber

Specification

| ITEM / MODEL | TY-NWMB60-09S | TY-NWMB80-16S |

| Max. capacity | 60 kgs / hr | 90 kgs / hr |

| Max. line speed | 10-40 m / min | 10-40 m / min |

| Melt-blown gsm | 20-35 gms / m2 | 20-35 gms / m2 |

| Screw diameter & L/D ratio | 60 mm / 32D | 80 mm / 32D |

| Melt-blown die width | 960 mm | 1680 mm |

| Slitting cloth roll | 5 rolls | 9 rolls |

| Max. diameter of roll | 600 mm | 600 mm |

| L x W x H | 10000 mm x 4500 mm x 5500 mm | 9200 mm x 3700 mm x 5400 mm |